Osmosis – the interplay between saline and non-saline solutions has existed in nature for millions of years in the cells of living organisms. A membrane, which is only permeable to fresh water and vital minerals regulates the liquid pressure and the salt content of the cell. This sophisticated process, which has always existed in nature can today be reversed and used as a technique for the desalination of seawater with a great potential for the future. We invert the natural process by regulation of the salt content trough the liquid pressure – this is Reverse Osmosis. The result is drinking water, which complies with the stringent requirements of WHO directives.

Seawater desalination by reverse osmosis technology has gained increasing importance in many countries faced with a shortage of water for domestic and industrial use.

Aqua Engineering designs and supplies RO systems to any required capacity.

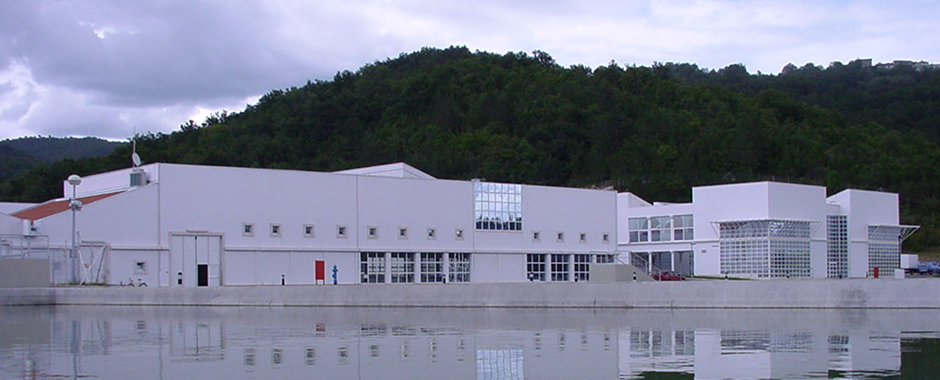

The largest capacity of SWRO plant successfully delivered by Aqua Engineering in 2013 is the 90.000 m3/day Hamriyah Phase II desalination plant with DAF + UF pre-treatment, located in the Emirate of Sharjah, United Arab Emirates. The first commercial SWRO plant has been commissioned by Aqua Engineering in 1989 and was a 4.550 m3/day plant located in Ajman, United Arab Emirates, which was successfully operated by the owners for a period of 20 years.

Desalination of seawater is usually done through membrane technology with reverse osmosis (RO) or thermal processes, which are commonly used in conjunction with power generation using waste heat from generation. Otherwise standalone the RO process is widely used due to its lower specific energy consumption (electric power) compared to thermal processes.

Seawater contains a significant concentration of dissolved salts (mainly NaCl) and is commonly also referred as salt water. Seawater has a salinity of roughly 35.000 ppm, equivalent to 35 grams of salt per one litre (or kilogram) of water.

Salinity in seawater varies at locations with highest salinities in the Persian Gulf up to 45.000 ppm and more in shallow and logged areas.

Also for seawater RO (SWRO) systems, pre-treatment of feed-water prior to salinity removal is of high importance to ensure stable and reliable plant operation; biological fouling due to high organics in seawater are common problems in RO plants, which require design experience and application knowhow. Beside conventional multi media filtration (MMF), advanced methods like dissolved air flotation (DAF) and/or ultra filtration (UF) are used today.

Reverse Osmosis (RO) is a process in which both dissolved organics and salts are removed using a mechanism different from distillation, ion exchange or activated carbon. The pressurized feed water flows across a membrane surface with a portion of the feed permeating the membrane. The balance of feed sweeps parallel to the surface of the membrane to exit it without being filtered. This type of system is called crossflow filtration.

The basic process of RO simply requires a pump, membrane pressure housing, membrane element(s) and plumbing connections. The number of membrane elements used in each desalination system is related to the quantity of water produced by the system. There are many types of membranes, each characterized by a particular salt rejection. The pump is used to pressurize the feed water to create the RO effect and distribute the fresh water to storage.

Seawater RO has a conversion rate in a range of 35 to 40 percent, which means 35 to 40 percent of the feed water is permeated and the remainder is concentrated to be returned to the water source(s). The conversion rate achievable depends on salinity as well as specific ions in feed water, which may precipitate on the membrane surface if conversion rate is too high; antiscaling chemicals are widely used to operate membrane systems at higher concentrations of critical ions to avoid precipitation (scaling) at membrane surfaces.

RO, using the first crossflow membrane separation, was the first to be widely commercialized. An advantage of crossflow filtration is that the impurities concentrated on the membrane surface are constantly swept away by the concentrate stream, thus continually cleaning the membrane surface. This prolongs its life, reduces fouling of the membrane surface and reduces maintenance costs. Another advantage of the RO process is that it removes most organic compounds and up to 99.5 percent of all ions. In contrast, conventional filters accumulate the captured, non-dissolved impurities on the filter medium and must be periodically cleansed and/or replaced.

Multi Media Filtration (MMF) - Conventional pre-treatment systems for SWRO were developed based on existing technology and most commonly consists of conventional media filtration. Single or dual stage granular media filters consisting of sand and anthracite (pumice was also successfully used) are typically applied in conventional pre-treatment systems, in gravity or pressurized configuration. Sand and anthracite filter beds are superior to single media filtration in that they provide higher filtration rates, longer runs and require less backwash water. In SWRO pre-treatment, the primary function of MMF is to reduce high loads of particulate and colloidal matter (i.e., turbidity).

MMF relies on depth filtration to enhance RO feed water quality. However, when high concentrations of organic matter or turbidity loads are encountered, coagulation is required to ensure that RO feed water of acceptable quality is produced (target SDI < 3).

Dissolved Air Flotation (DAF) is a clarification process that can be used to remove particles prior to conventional media filtration or MF/UF systems. Raw water is dosed with a coagulant, typically at concentrations lower than those applied for sedimentation, followed by two-stage tapered flocculation. Removal is achieved by injecting the feed water stream with water that has been saturated with air under pressure and then releasing the air at atmospheric pressure in a flotation tank. As the pressurized water is released, a large number of micro-bubbles are formed that adhere to coagulated flocs and suspended matter causing them to float to the water surface where they may be removed by either a mechanical scraper or hydraulic means, or a combination thereof. Clarified water (sub-natant) is drawn off the bottom of the tank by a series of lateral draw-off pipes. Recent DAF systems have been developed for high hydraulic loading rates, which require a smaller footprint than sedimentation as result.

Ultrafiltration (UF) has been considered as a more reliable alternative to conventional multi media filtration (with and without coagulation) as a pre-treatment process for RO systems over the last decade. UF membranes have been tested and applied at pilot and commercial scale as pre-treatment for SWRO and offer several advantages over conventional pre-treatment systems; namely, lower footprint, constant high permeate quality (in terms of SDI), higher retention of large molecular weight organics, lower overall chemical consumption, etc.

UF membranes are generally more effective in removing particulate and colloidal matter from seawater than MMF. Hence, they are expected to be more reliable in maintaining an RO feed water with low fouling potential however at higher cost than conventional MMF.